The Silent Killer: Why 60% of Dropshipping Stores Fail at Scale

Fluctuating costs and inventory gaps can wipe out your margins overnight. Here are the 3 supply chain protocols to secure your business.

You’ve finally found a winning product. Sales are pouring in. But suddenly, you wake up to a nightmare: your supplier quietly raised the price by $5, eating your entire margin. Or worse, you sold 50 units overnight, only to find out the factory is out of stock.

This is the "Silent Killer" of dropshipping. Most beginners focus on ads but ignore backend stability. The pros? They use automated watchdogs.

In this guide, we’ll break down the 3 specific protocols you need to protect your margins and reputation.

Click here to start dropshipping now with DSersIn This Post

Protocol 1: The "Real-Time" Shield (Inventory Sync)

The Hidden Leak in Your FunnelImagine spending $500 on ads today, driving 20 customers to your store, only to realize later that the product is out of stock at the factory. You now have to refund 20 people and explain why you failed. This isn't just lost revenue; it's a "death sentence" for your Facebook Ad Account score and payment gateway reputation.

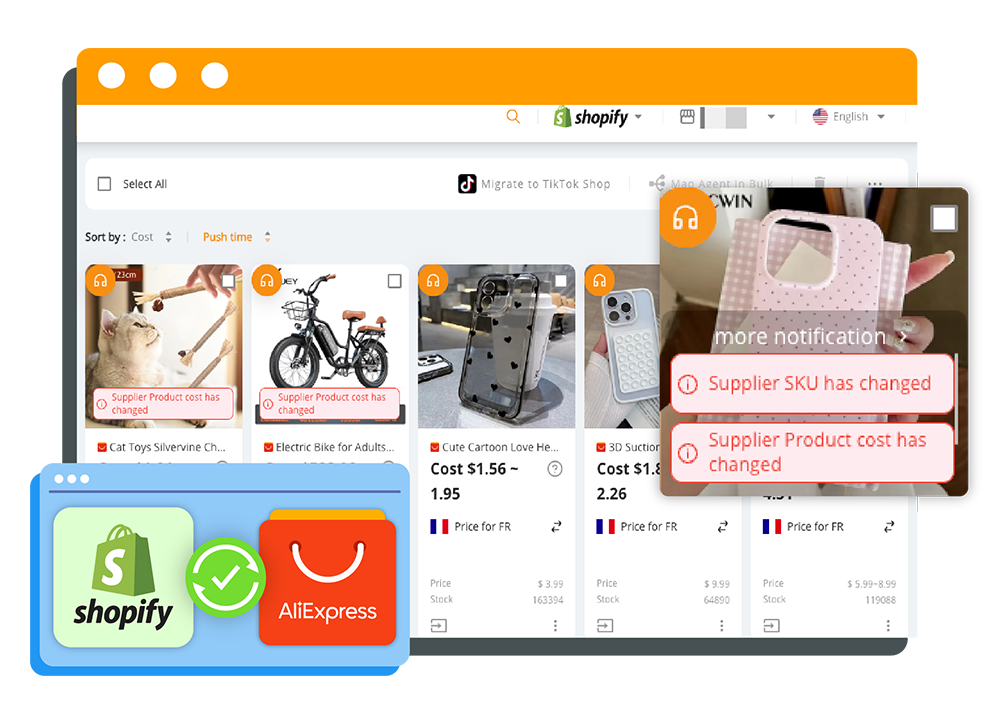

The Strategy: Zero-Latency DataYou cannot rely on manual checks. By the time you wake up and check AliExpress, the stock might have changed hours ago. Successful merchants establish a "Zero-Latency" connection. You need a system that mirrors the factory's warehouse status to your storefront in real-time. The moment a SKU hits zero in China, your "Buy Now" button should automatically disable.

Implementation:Most advanced fulfillment platforms handle this via API. For instance, if you are using DSers, enabling the "Inventory Auto-Sync" setting effectively builds this firewall for you, ensuring you never sell a ghost product.

Protocol 2: The "Profit" Protection (Dynamic Pricing)

The Margin TrapNew dropshippers often set a static price and forget it. But suppliers don't. Raw material costs and currency fluctuations mean your product cost can jump from $10 to $14 overnight. If you're still selling at the old price, your profit margin just evaporated, and you might even be paying customers to take your product.

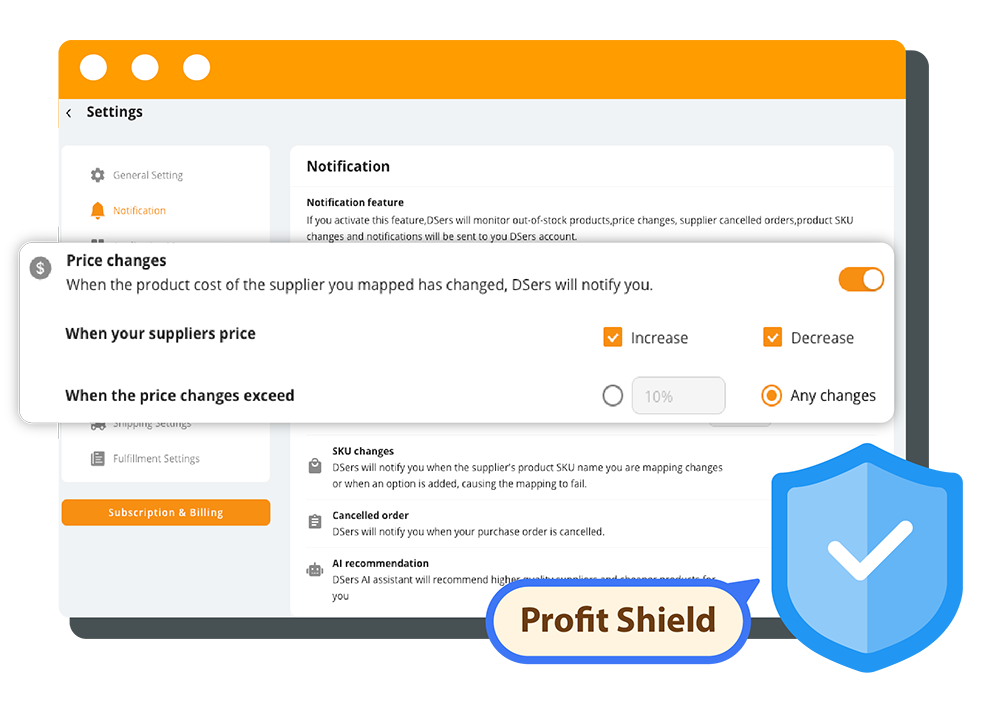

The Strategy: Rule-Based PricingYou need a "watchdog" mechanism. The goal is to set a Dynamic Pricing Rule: If Cost Price increases, Retail Price must increase automatically.This protects your baseline. You shouldn't be the one absorbing the inflation; the market price should reflect the cost.

Implementation:Instead of checking costs daily, automate the logic. In your fulfillment dashboard settings (such as the "Auto-Update" tab in DSers), you can set a rule to "Update Store Price" whenever the supplier adjusts their cost. This is the only way to guarantee your margin remains healthy while you sleep.

Protocol 3: The "Redundancy" Plan (Backup Suppliers)

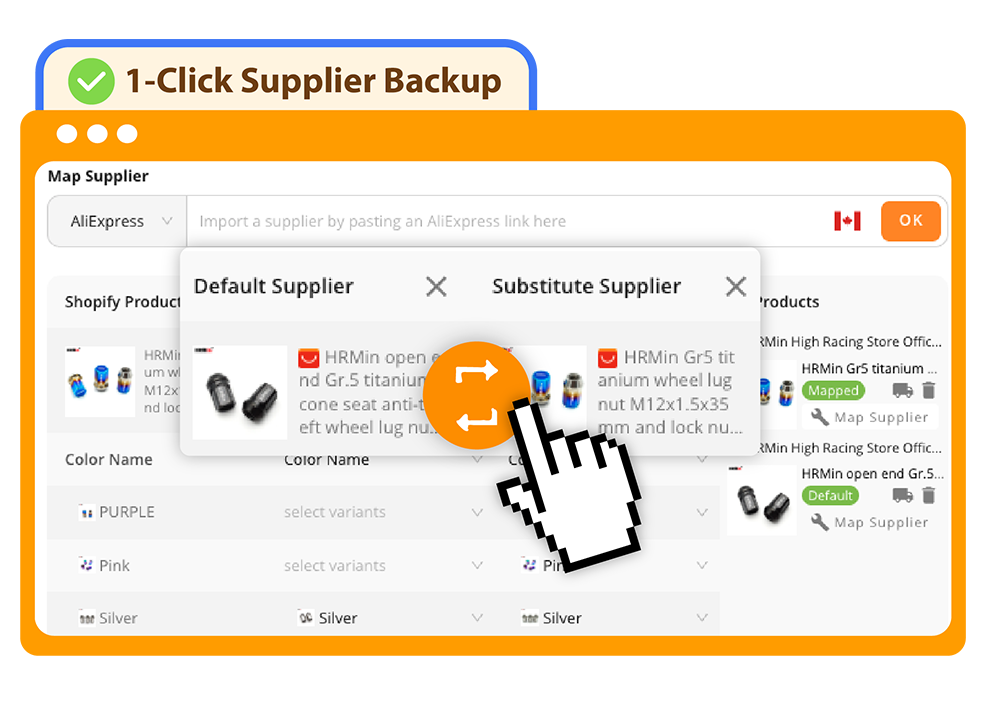

The Single Point of FailureRelying on a single supplier is the biggest rookie mistake. What if they go on holiday? What if they run out of raw materials? Your entire business pauses, but your ad spend doesn't. This "Single Point of Failure" is why scalable businesses prioritize Redundancy over loyalty.

The Strategy: Multi-Sourcing MappingProfessional operations always have a "Plan B" pre-loaded. The concept is Product Mapping. You verify a primary supplier for daily orders but identify a secondary supplier selling the exact same item. When Supplier A fails, you don't scramble to search; you simply flip a switch to route orders to Supplier B.

Implementation:This is difficult to manage on spreadsheets but easy with software. Tools like DSers allow you to "Map" multiple suppliers to a single product variant. If your primary source goes dark, you can switch fulfillment to your backup instantly, keeping your business running without the customer ever knowing.

💡Risk Management Tips

- Set Notification Rules: Don't just let the software auto-update everything silently. Configure DSers to send you an email notification when a price changes drastically. You want to know why the price jumped.

- Buffer Stock: If possible, set your inventory rules to show "Sold Out" when the supplier still has 10 units left (not 0), just to be safe against data delays during peak seasons like Black Friday.

📝When to Enable These Protocols

- Scaling Phase: Once you get more than 10 orders a day, manual checking becomes impossible. Enable these protocols immediately.

- High Volume Periods: During Q4, stock monitoring is non-negotiable as inventory fluctuates wildly across all of China.

Frequently Asked Questions

Why does my supplier change prices so often?

It isn't personal; it's economics. Raw material costs, currency exchange rates, and sudden spikes in demand can all cause suppliers to adjust pricing dynamically. The risk isn't the change itself, but failing to react to it immediately.

Can I just check prices manually every morning?

You can, but it's a dangerous gamble. If a price hikes at 2 PM and you get 50 orders before checking again the next morning, you've already lost significant margin. Automation removes this expensive "time gap" and protects your profits 24/7.

What if the automated update makes my product too expensive?

Control is key. Advanced tools don't just blindly update; they follow your rules. In DSers Auto-Update settings, you can choose to "Notify Only" instead of auto-updating. This gives you the final say: absorb the cost, raise the price, or switch to a backup supplier.

Company

Company

Why Choose DSers

Why Choose DSers

Blog

Blog

Help Center

Help Center

Live Chat

Live Chat